Contents

In the wake of the COVID-19 pandemic and the advent of ethical concerns in fashion, designers have a lot to consider when deciding how their products should be made.

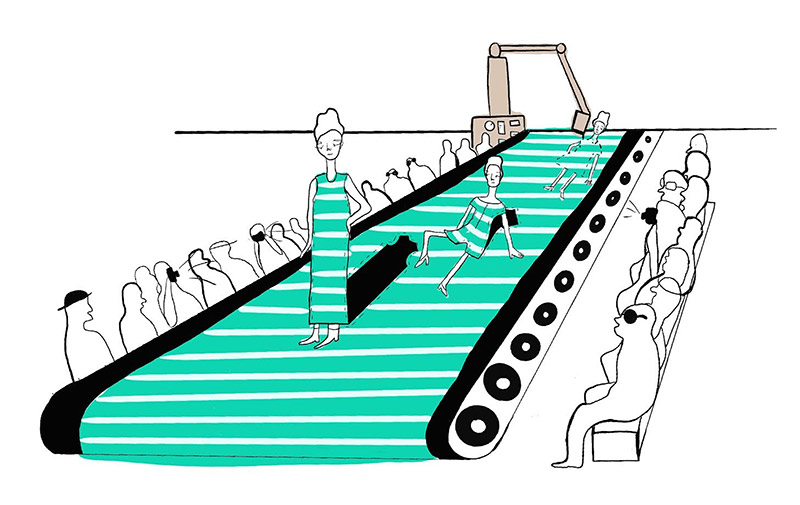

Everyone from Vogue to Amazon has weighed in on the new craze for on-demand manufacturing. This on-demand model has taken the fashion world by storm and may offer a solution to many of the external considerations shaping today’s business world.

Where Taxis have Uber, Hotels have Airbnb, it seems on-demand manufacturing is the apparel industry’s newest international craze.

What is On-demand manufacturing?

On-Demand manufacturing is a production model when goods are only made when or as they are required. In the fashion industry, this is also called made-to-order. Here, brands will not send the quantities they need to their manufacturers until their customers have directly ordered the product. This also usually involves paying for the item up-front. This often leads to longer wait times for the customers, as the product has not yet been made by the manufacturer at the point of order.

You will have a period where you call out to your customers for orders and then itemize them once received. Then you send these orders directly to your manufacturer where they will be produced. For large-scale, high-cost items, it may be possible to send orders on a per-product basis. You can then choose whether they will be sent directly from the factory (a.k.a Drop Shipping) or back to you where you can send them to customers at your leisure. This means absolutely no wastage.

The on-demand model differs heavily from traditional wholesale manufacturing that relies on, usually seasonal, bulk orders of products that designers hope customers will buy. A problem with this form of production is that it often leads to a large amount of dead stock and product wastage. With rushed production lines to fulfill seasonal quotas, it is also possible that wholesale production can compromise on product quality.

On-demand manufacturing does not require products to be stored while waiting for customers to order them. Thus all items are manufactured in response to customer demand. From a manufacturing perspective, this allows more time for orders to be delivered as it is not on a seasonal basis. This may mean products can be made to the exact specifications or to a higher quality. It is also one of the ways to shorten time-to-market.

On-demand manufacturing has become even more influential in recent years, as designers look to refocus their business models and put both ethics and economy at the top of their priorities list.

The benefits of On-demand manufacturing

We had the chance to chat with Head Designer and Founder of Ajaie Alaie - Daniella Samper, who gave us her insight into why on-demand manufacturing may become the future of fashion. She gave a whole host of reasons why this new form of manufacturing is taking over independent fashion brands and what this might mean for the future of business.

1. It offers a more ethical alternative for designers

One of Daniella’s main inputs about the role of on-demand manufacturing is that it’s simply a more ethical choice. It reduces the energy and pollution of shipping stock that will not be sold and therefore used. It also means that, as a designer, Daniella is able to have more input into her design process as she is not pressured by seasonal deadlines in the same manner as wholesale designers. It also ‘slows’ fashion down and reduces the danger of products being produced in unregulated factories for the sake of saving time. Given the demand for ethical fashion, this ‘slower’ model may actually provide faster profit opportunities for brands.

2. Less wastage

Less wastage is one of the major benefits of the on-demand model. According to data from the Environmental Protection Agency, US landfills received 11.3 million tons of MSW textiles in 2018. This was 7.7 percent of all MSW landfilled products. With on-demand manufacturing, brands are only producing stock they have already sold. This saves on having an excess product that would otherwise go to landfill and the cost of producing this stock in the first place. This gives two for the price of one in benefits to the designer.

3. Better relationships with your manufacturers

One of Daniella’s other major takeaways from her move to the on-demand model was that it had improved her relationship with her manufacturers. This benefit links with the other ethical considerations of the on-demand model, seen above. According to Daniella, she experienced stronger relationships with her manufacturers as she could offer them higher-cost orders with more notice. This means that her factories do not need to engage seasonal workers to produce her products. This ensures more consistent opportunities for manufacturers, leading to more ethical hiring practices and less economic concerns over seasonal demands.

4. Higher-quality products

The shorter lead time combined with a longer production schedule means that on-demand products are usually of better quality than their wholesale counterparts. Production times can also be advertised to customers in advance so manufacturers and designers get the time they need to ensure that their products are of the best quality possible.

5. Greater control over your business

One of the most important benefits of on-demand manufacturing is the control it gives to the designer over their product. In the wholesale model, brands are often at the behest of market demands and the need to shift dead stock. However, when following on-demand manufacturing, brands can understand exactly what products are in high demand and ensure that the right amount of those products is produced. This also helps brands keep in touch with what changes in fashion are popular so that they can motivate stock to fulfill these demands quickly, without having to wait for seasonal stock changes.

Daniella also touched on her personal motivations for moving to an on-demand model. She argues that it allowed her to slow down her business which actually hastened and improved her business output. By retaking this control, Daniella found her business became more productive and popular than ever before.

6. Wider opportunities for manufacturers

The on-demand model does not just benefit designers. It also heavily benefits manufacturers who face less seasonal time pressure as a result of wholesale ordering. By ensuring an on-demand manufacturing flow, manufacturers can have greater notice and lead times to plan themselves for making products. This also ensures the hiring of a greater number of skilled garment workers, rather than seasonal workers, which helps to foster more ethical and sustainable business practices for all parties involved.

7. You can get your business started right away

One of the most difficult arenas in business is actually getting started and taking your designing feet off the ground. On-demand manufacturing offers a relatively low-risk introduction to design, as it does not rely on inputting a large amount of start-up capital for wholesale stock. There is also no obligation to remain with a manufacturer if their product is not made to the desired quality. Finally, on-demand manufacturing is also heavily facilitated by online, ‘instant’ ordering, which allows you to build up a network of customers quickly and efficiently to get your business going.

How to use technologies to adopt on-demand production model

A number of new technology platforms exist to make on-demand production even easier. Sharecloth, a retail software company, uses cloud-based technology to help promote the on-demand model. This technology allows you to make 3-D models of your products, as well as the option to receive custom orders directly from their website.

An alternative software, UnmadeOS, ‘is an operating platform that enables fashion and sportswear brands to connect demand to product and production.’ Their software allows you to design, and then manufacture, your products, all through their operating system.

Likewise, Techpacker is also the ideal tech solution for anyone interested in starting out with on-demand production.

The starting point of all manufacturing is the tech pack: whether you’re working with the traditional or on-demand model. Techpacker is there to help facilitate the design, organization, and then sending off your products to your manufacturer.

On Techpacker, our software allows you to build your tech pack through Cards.

Cards offer the perfect interface for brands to create their on-demand order. They can be annotated with attached comments or images, making the needs of your order clear to the manufacturer.

We also have a selection of ready-made cards in our Explore Library which give you a good starting point if you are looking to design a new product.

Our Library structure also allows you to save card information such as the fabric’s description, quantity, color, cost, and the supplier’s contact information. This means that if you need to send further orders quickly, you can have all the information saved and ready to go. All you need to do is drag and drop the relevant card information into your tech pack and it can then be sent to your manufacturer.

This means that the on-demand model is now easier than ever and can be done on Techpacker instantly: let us do the hard work for you.

|

Interested in learning more about Techpacker? OR Request a demo

Manage your product development to production workflow with factories hastlefree. Try Techpacker. |